Wire Mesh Machine Series

-

GALVANISE LEKHOTA

LITŠOANTŠISO: TŠEPE YA CARBON Q195

LIKOPO:FACILITA THE PLTŠEBELETSO EA TŠEBELETSO EA GRESENAHA RESMATS'ELA LE HO Ntlafatsa TSHEBETSO EA TŠEBELETSO EA LIBAKA LE KA NTLEHO EA KHULISO. KA NAKO E TŠOANA, E SEBELE LE HO HLOMELA LELAPA.

MAFAMAMA A NA LE LIhoai LE BARUSI, HO HLOMELA TŠIRELETSO EA MOEDI, LEKHOAOA LA MApolasi, NKOANE EA MEHLA, HO TLOA DITHABELA HO FUMANA LIBAKA, HO KHABELLA LIBAKA TSA BOHALE LE MAQAO A TSOMI, LE HO IKAOA LE HO HLOKOMELA LIBAKA TSA KAHO.

-

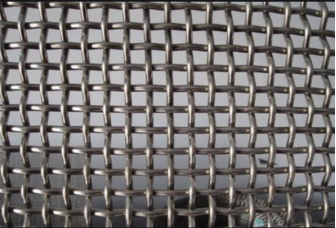

KEKETSO LEKHOPO LEKHOPO

LITŠOANTŠISO: terata ea tšepe e PHAHAMENG E PHAHAMENG, terata e KHABANE, terata e sa hloekang ea tšepe, terata e apesitsoeng ea PVC.

TŠEBELETSO: E SEBELISA TSIMENG HAEBA HO ARCHITETURE, TABA EA HO BAPALA, LEKHOAOA LA HO GREEING, WATERWAY, SIRELETSO EA BOLULO, jj.

TLHOKOMELISO LE LITŠOANTŠISO:KAMANO LE HO LOHELA,HO SEBELISA HO BONOLO, HO BONAHALA LE HO SEBELISA.

-

HEXAGONAL terata

TLHOKOMELISO: terata ea TŠEPE EA KHABONE E PHAHAMENG E TLASE, terata e sa hloekang.

LITLHAKISO TSE FUMANENG:

TŠEBELANG E KBITSOE GALVANIZED KA MOR'A HO LOHELA.

TŠEBELANG E KBITSOE GALVANIZED PELE HO LOHWA.ELECTRO GALVANIZE MOR'A HO LOHELA.

ELECTRO GALVANIZED PELE O LOHALA.PVC E TLATSOE.

TŠEBELETSO: E SEBELISA HAHOLO MOAhong, OLI, MOKHAHONG OA K'hemik'hale, LEFUSO, TIRELETSO EA LIMELA, MATLAFATSO EA TS'EBETSO EA LIJO, TSELA LE HO BOLOKA MOCHESO. -

GALVANIZED WELDED terata KHOA

TLHOKOMELISO: THARA EA TŠEPE EA KHABONE E PHAHAMENG E TLASE

TŠEBELETSO: WELDED WIRE MESH E SEBELISA HAHOLO LIITEKENG LE TEMO, MOAhong, LITSAMAI LE MOEPO BAKENG SA MORERO OA TSOHLE JOALOKA MATLO A KHOHO, LIBASKETE TSA MAHE, TŠEBELETSO EA RUNWAY, RACK YA HO DIRA, LITHOLOANA, HO OMETSA LITHOLOANA.

-

KHOPOTSO LEKHOPO

TLHOKOMELISO: terata ea tšepe e ntšo, terata ea tšepe, jj.

TŠEBELETSO:E SEBELISA HAHOLO MINE.COAL FACTORY,CONSTRUCTION ETC,PROFESSIONS.

-

PHAnele E TS'ELISITSOE terata

TŠEBELETSO: GALVANIZED WELDED MESH PANEL E ENTSOE KA MASH OA BOHOLO OA KHETHEHILENG, E NA LE BOARA LE BOARA, KAHO EA FEME, E SEBELISA HAHOLO HO AHA, LIJO, TEMO BAKENG SA EXPRESSWAYS, LITLOA TSA TERE, LIBUKA, LIPANSI, LIPANSI, LIPANSI, LITŠOANTŠISO.

-

Mohala o Motsu

terata e hlabang e sothehile ebile e lohiloe ke mochini o itirisang ka botlalo oa terata e hlabang. Mefuta ea lihlahisoa tse felileng: braid e sothehileng ea monofilament le braid e sothehileng ka makhetlo a mabeli. Lintho tse tala: terata ea tšepe ea boleng bo phahameng e tlase. Ts'ebetso ea kalafo ea bokaholimo: sekontiri sa elektro-galvanized, sekontiri se chesang, se koahetsoeng ka polasetiki, se fafalitsoe. E fumaneha ka mebala e putsoa, e tala, e mosehla le e meng. Lisebelisoa: E sebelisoa bakeng sa moeli oa lekhulo, seporo, tšireletso ea ho itšehla thajana ho litsela tse kholo.

-

Razor Barbed Wire

Ha o hloka ho teba ka ts'ireletso, Razor Barbed Wire ke tharollo e molemohali. E batla e le theko e tlaase, empa e sebetsa ka sehlōhō. Razor Barbed Wire e pota-potileng pherimitha e lekane ho thibela mang kapa mang eo e ka bang sesenyi, lesholu kapa senokoane. Razor Wire e entsoe ka lente le sehang la tšepe le sa bolaeeng le phuthetsoe ho pota-pota khubu ea terata ea tšepe ea selemo. Ho ke ke ha khoneha ho seha ntle le lisebelisoa tse khethehileng haholo, 'me leha ho le joalo ke mosebetsi o liehang, o kotsi. Razor Barbed Wire ke tšitiso e tšoarellang nako e telele ebile e sebetsa haholo, e tsebahalang ebile e tšeptjoa ke litsebi tsa ts'ireletso.

-

Hexagonal Mesh Machine

Ts'ebetso e boreleli, lerata le tlase, lebelo la ho loha ka potlako. Thepa eohle e tsamaisoa ke enjene ea 2.2KW, e bolokang motlakase. Ho boloka mosebetsi o mongata, ka lebaka la ho felisoa ha mokhoa oa selemo, sesebelisoa se le seng se lekane, basebetsi ba nang le boiphihlelo ba ka sebetsa tse peli. thepa.

-

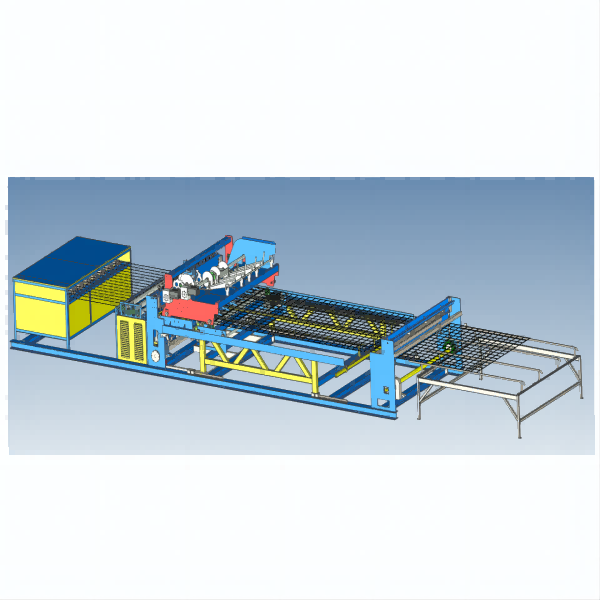

Mochini oa ho Welding oa Wire Mesh

Tsebisa:

Khamphani ea rona e amohetse theknoloji e tsoetseng pele ea taolo ea lapeng motheong oa maeto a masimong ho latela litlhoko tsa basebelisi, e akaretsa boholo ba moreki ts'ebelisong ea mefokolo ea mochini oa khale oa welding, e ntlafatsa nts'etsopele ea ts'ebeliso e atlehileng ea thekenoloji ea taolo ea synchronous, nako ea welding le sub. -control welding e entsoe ka sistimi ea dijithale ea PLC, welding e ka fetoloa ka har'a lethathamo le boletsoeng la taolo e nepahetseng, ts'ebetso e tsitsitseng eo karolo ea eona e kenang skrineng sa ho ama, ts'ebetso e bohlale haholoanyane, e lekantsoe, 'me e na le compression, petsoha. litšobotsi. Rationalization, 'me e na le compression, sub-welding litšobotsi. Monyetla o moholo ka ho fetisisa oa mochine ke: o ka hlaha marang-rang a tšoanang pakeng tsa likoti le likoti tse 30 tsa boholo bo fapaneng ba likoti, terata ea weft ho otlolla le ho khaola ka har'a funnel ho sebelisa mochine oa stepper ka tsela e iketsang e oela terata, terata ea ho oa ha e tloaelehile, thepa e emisitsoe ho fihlela terata ea ho oa e tloaelehile, ho hula marang-rang ho sebelisa servo motors ho etsa hore grid e be bonolo ho lokisa, ho nepahala ho phahameng ha boholo ba marang-rang, servo motor e ka ba cyclic e hula marang-rang, kaho ea kaho e iketsang coil letlooeng line welder lebelo, feela hloka batho ba 2 ba ka qeta ts'ebetso, e bonolo ebile e bonolo ho ithuta. Sehlahisoa se ka phuthoa, se beha palo e hlokahalang ea limithara ho skrineng sa ho ama ha se tsoa, thepa e tla emisa ka bo eona ha e fihla ho palo ea limithara, 'me e ka boela ea tsoa filiming,' me filimi e tla ikemela. sehiloeng ke seha sekirini ka mor'a hore ho phethoe ho hula letlooeng le le leng, 'me terata ea warp ke thepa e phuthetsoeng ea motho.

-

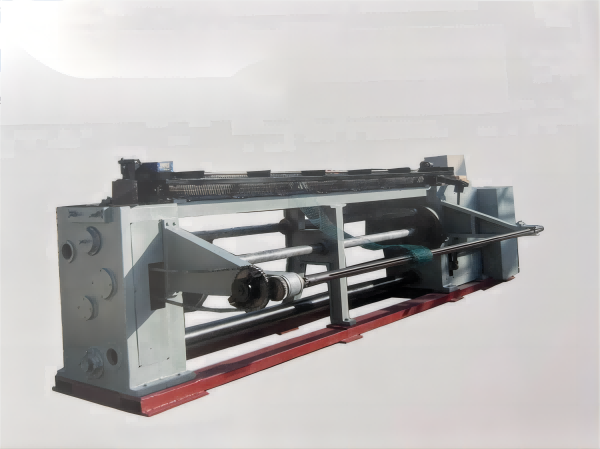

Mochini o cheselitsoeng oa letlooeng

Lekanya bolelele ba pheletso ea terata ea weft ho latela sistimi ea taolo ea ho taka letlooa 'me u e tlalehe ka har'a komporo,' me ka nako e ts'oanang u romelle terata ea weft ho sesebelisoa sa welding bakeng sa welding ea othomathiki; terata ea warp e romeloa ka bo eona ho terata e latelang ea weft ka mochine oa ho tjheseletsa oa motlakase; 'me ka tsamaiso ea taolo e phethela ts'ebetso eohle ea ho hula letlooa.

-

Mochini oa marang-rang oa Grassland

Tšebeliso ea mochini:

E sebelisetsoa matlooa a joang, matlooa a likhomo, malapa a litsebi tsa temo le liphoofolo ho theha mapolasi a malapa ho theha tšireletso ea moeli,

Tlhahiso le tlhahiso ea terata ea moeli oa masimo, libaka tsa meru, ho koaloa ha lithaba, libaka tsa bahahlauli le libaka tsa ho tsoma li etsa joalo.